Multi layer laminated Teflon coated fiberglass cloth, high tensile heavy duty belt

Teflon coated fiberglass cloth can be laminated with multi layers PTFE fabric, which will highly enhance the tensile strength than normal Teflon coated fabric.

This laminated PTFE fabric is made into heavy duty belting, which need long lifetime and high tensile strength, such as food processing like Tortilla, pizza, or flooring industry for PVC & PU curing and cooling. And conductive PTFE laminated belt for tabber stringer machines.

Why use Multilayer laminated Teflon coated fiberglass cloth?

PTFE laminated fabric is laminated by two or more layers PTFE coated fabrics, which has much higher tensile strength and tear strength than normal PTFE fabric.

In this case, PTFE laminated fabric is suitable for applications working in tough environment, especially used for making belt for food processing, rubber & polymer curing, solar industry and so on.

Property of PTFE coated laminated fabric

★ Superior non stick & easy release

★ Excellent dimensional stability and high tensile

★ Outstanding heat resistant, can continuous working from 73°C to +260°C

★ strong chemical resistant

★ UV resistant

★ FDA & LFGB certificated

★ High dielectric constant

Applications of laminated Teflon coated fabric

1) Curing of Rubber and Polymer

Laminated Teflon coated fiberglass cloth is used to replace the heavy steel belt in vulcanizing machines.

Due to this PTFE laminated belt can resist high temperature, has high dimensional stability & high tensile, non stick & easy release and is much cost effective than endless heavy steel belt.

2) Tabber stringer belts

Two layers laminated Teflon coated fabrics is workable for this industry, in order for increasing the lifetime of the belt, and minimum the off time in the production line. The quality of PTFE coated belt is important to the final quality of product.

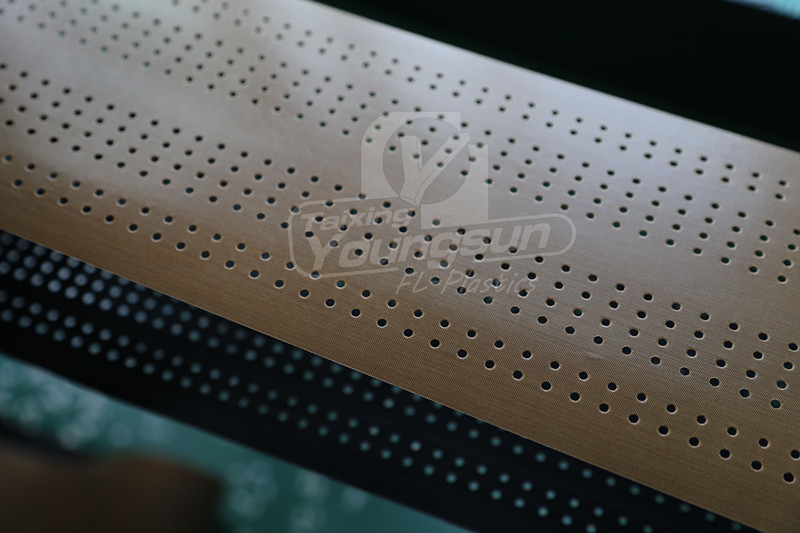

Different holes in line is available for different machines, such as 2, 4, 6, 8, 12 holes in line. Which means the porosity of this belt is adjustable.

3) Food processing industry

PTFE laminated belt is workable for heavy duty industry, especially for food processing industry, since this working environment is high oil and high pressure. Which has high request of the non stick property and high tensile strength.

4) Luxury Vinly Tiles manufacturing

Laminated Teflon coated fiberglass cloth is used as release belt for flooring industry, due to the high tensile strength and excellent release surface. One upper belt and one lower belt will be used for the heat press machines.

Two or more layers of PTFE coated fabric can be laminated, in order for enhance the tensile strength and mechanical strength.

Belting of PTFE fabric can be punched different holes in line, for increasing the porosity of belt.