Modified PTFE Adhesive Fabric

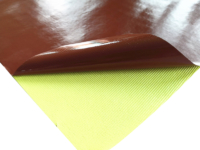

Modified PTFE Adhesive Fabrics are coated with high content PFA(Polytetrafluoro ethylene) on the top, which is specially designed to achieve higher performance in welding property, non stick property, mechanical strength, anti oil property and others.

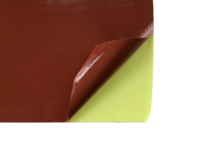

Because of the excellent quality improvement, PTFE adhesive fabric modified series can meet higher request in customer’s applications. And ESONE offer special red color to mark the modified series.

Properties of Modified Teflon Adhesive Fabric

- Higher glossy surface

- Super easy release surface

- Better welding property

- Superior anti oil property

- Stronger mechanical strength

- Excellent long lasting property

- Higher dielectric strength

What is the difference between PFA and PTFE

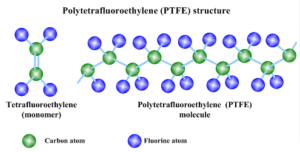

PTFE(polytetrafluoroethylene) is a synthetic fluoropolymer of tetrafluoroethylene, which is a high-molecular-weight compound comprised of carbon and fluorine. Other than Teflon, PTFE is also commonly called as Fluon and Syncolon.

PTFE is popularly used as a non-stick coating for pans, cookware or fiber. PTFE is often used in containers and pipes for handling reactive and corrosive chemicals, this is due to its non-reactive properties.

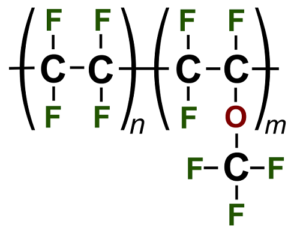

PFA, or Perfluoroalkoxy, is a type of fluoropolymer. It has very similar properties as polytetrafluoroethylene (PTFE). What distinguishes it from the resins of PTFE is that PFA is melt processable.

PFA is generally used for plastic lab equipment because of its optical transparency, overall flexibility, and extreme resistance to chemical attack. PFA is also often used as tubing for handling critical or highly corrosive processes. Other applications for PFA are as sheet linings for chemical equipment.

PFA is superior to PTFE in terms of flexibility, particularly when it comes to tubing applications. On the other hand, PFA’s flex life (capacity to endure repetitive folding) is lower than that of PTFE. PTFE is slightly more resistant to heat than PFA. PFA is more affected by water absorption and weathering but is superior to PTFE when it comes to salt spray resistance. The most significant quality of PFA over PTFE is its electrical properties. It possesses the dielectric constant of PTFE as well as a very similar dissipation factor; yet PFA has a dielectric strength three to four times higher than that of PTFE.

Specification of Modified PTFE Adhesive Fabric

| PFA top coated adhesive Fabric Modified Series | ||||||||

|---|---|---|---|---|---|---|---|---|

| Style | Standard Width(mm) Please ask for other widths | PFA Content (%) | Backing Thickness (mm) | Total Thickness (mm) | Weight (g/m2) | Adhesive (N/cm) | Tensile Strength Warp/Fill (N/cm) | Color |

| YS7008AJ-M | 1000, 1250 | 10 | 0.08 | 0.13 | 155 | 4.4 | 104/98 | Red |

| YS7013AJ-M | 1000, 1250 | 11 | 0.13 | 0.18 | 270 | 5.4 | 240/200 | Red |

| YS7015AJ-M | 1000 | 11 | 0.15 | 0.20 | 316 | 5.6 | 240/200 | Red |

| YS7018AJ-M | 1000 | 11 | 0.18 | 0.23 | 370 | 5.6 | 320/302 | Red |

| YS7020AJ-M | 1000 | 10 | 0.20 | 0.25 | 410 | 5.7 | 280/256 | Red |

| YS7025AJ-M | 1000 | 10 | 0.25 | 0.30 | 530 | 6.0 | 460/400 | Red |

| YS7030AJ-M | 1000 | 8 | 0.30 | 0.35 | 625 | 6.2 | 680/640 | Red |

Get Social