Pharmaceuticals

ESONE PTFE casting films, virgin skived PTFE films, and PTFE film laminates are widely used as high-performance sealing materials in the pharmaceutical industry, as well as barrier layers in drug containers and delivery systems.

These specialty fluoropolymer films and laminates help extend product shelf life and ensure containment safety by acting as an effective barrier within pharmaceutical packaging. Thanks to the inherently inert nature of PTFE, ESONE materials will not react with drugs or packaging components. Typically laminated to sealing substrates, they deliver leak-proof performance while providing exceptional resistance to oxygen, bacteria, and moisture—ensuring product integrity and patient safety throughout storage and use.

Applications

ESONE PTFE Silicone Septa is die cut from PTFE film laminated PE foam or silicone sheet, which is designed for high performance sealing application. Our bottle cap liner can meet following critical requirements for 100% guarantee in pharmacy industry.

- Providing a barrier to oxygen, chemical and moisture.

- Secure contents safely and maintain the freshness of product with no leakage

- Preventing contamination for consumer safety due to the superior sealing performance

- Create an impermeable sealing even in corrosive and high temperature working environment.

TDS of PTFE/Silicone Septa Sealing Material for Pharmaceuticals

| Model Name | Film Thickness mm(mil) | Silicone Thickness mm(mil) | Tensile Strength MPa | Silicone Hardness Shore A | Color | Description |

|---|---|---|---|---|---|---|

| ESLAM SEP1 | 0.075(3) | 0.5(20) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

| ESLAM SEP2 | 0.075(3) | 1.0(40) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

| ESLAM SEP3 | 0.13(5) | 1.0(40) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

| ESLAM SEP4 | 0.13(5) | 3.0(120) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

TDS of PTFE/PE Foam Septa Sealing Material for Pharmaceuticals

| Products | PTFE Thickness (mm) | Total Thickness (mm) | Max Width (mm) | Foam Density g/cc |

|---|---|---|---|---|

| PTFE Film + PE Foam + PTFE Film | 0.05-0.13 | 1-3 | 1000 | 0.3-0.6 |

| PTFE Film + PE Foam + PE Film | 0.05-0.13 | 1-3 | 1000 | 0.3-0.6 |

In pharmaceutical research and production, accurate microbial testing and reliable gas analysis are critical for product quality and regulatory compliance. Traditional Petri dish covers can present challenges: liquid culture media may leak, dead cells can adhere to instruments, and sensors may become contaminated during oxygen or carbon dioxide monitoring.

To address these challenges, ESONE PTFE/Silicone composite films provide a high-performance solution for covering microbial culture plates while enabling precise gas detection.

How It Works

- Ultra Thin PTFE Film Layer

- Non-stick surface: The ultra-low surface energy of PTFE makes it inherently resistant to bacterial adhesion and biofilm formation, reducing contamination risks.

- Gas permeability: Ultra-thin PTFE film allows oxygen, carbon dioxide, and other gases to diffuse freely, while blocking liquid media and microorganisms.

- Chemical inertness: Completely non-reactive with pharmaceutical formulations and culture media, ensuring reliable test conditions.

- Silicone Rubber Layer

- Mechanical strength: Provides structural support, ensuring the composite film is easy to handle and securely seals onto culture dishes.

- Elastic sealing: Adapts to lids, dish rims, or analytical instruments, maintaining tight containment during testing.

Key Advantages of PTFE Silicone Composite Films

- Accurate gas detection: Enables continuous and non-interfering monitoring of O₂ and CO₂ concentration in cultures.

- Enhanced contamination control: Prevents liquid leakage and bacterial adherence to sensors, preserving measurement integrity.

- Reliable sealing performance: Gas-permeable yet liquid-tight, providing dual protection in sensitive applications.

- Extended sensor life: Reduces fouling and maintenance caused by microbial residues.

| Model Name | Film Thickness um(mil) | Silicone Thickness um(mil) | Silicone Hardness Shore A | Color | Description |

|---|---|---|---|---|---|

| ESLAM MT1 | 4(0.15) | 30(1.2) | 30, 40 | Black | PTFE Film/Silicone Rubber |

| ESLAM MT2 | 4(0.15) | 50(2.5) | 30, 40 | Black | PTFE Film/Silicone Rubber |

| ESLAM MT3 | 10(0.4) | 50(2.5) | 30, 40 | Black | PTFE Film/Silicone Rubber |

| ESLAM MT4 | 15(0.6) | 75(3) | 30, 40 | Black | PTFE Film/Silicone Rubber |

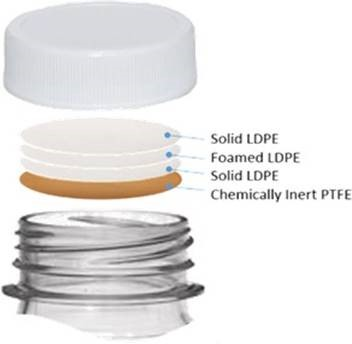

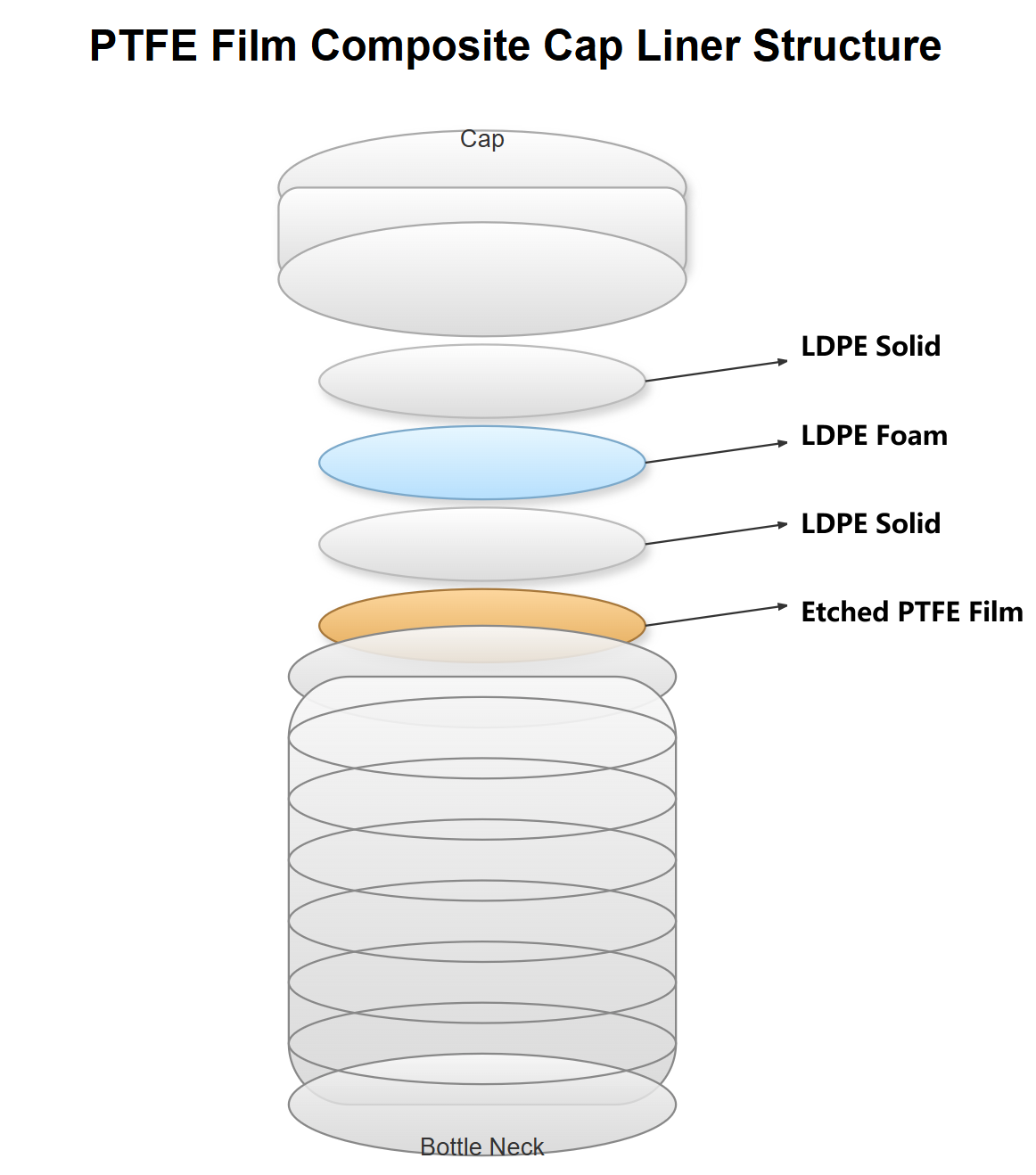

In critical packaging applications, where integrity, safety, and reliability are paramount, sealing materials must withstand chemical exposure, extreme temperatures, and repeated stress. ESONE PTFE/PE Composite Film, particularly the PTFE/LDPE laminated series, are engineered to deliver outstanding performance in these demanding environments. By combining the superior chemical resistance of polytetrafluoroethylene (PTFE) with the compressibility of polyethylene (PE) foam, these laminates provide a dependable sealing solution for pharmaceutical, food, beverage, and industrial markets.

Product Structure of PTFE PE Composite Foam

The PTFE/PE laminated series consists of a skived PTFE film laminated to PE foam and solid PE backings, available in a range of thicknesses.

This dual-layer design leverages the inert and durable characteristics of PTFE film with the cushioning properties of a foam backing to ensure both chemical protection and mechanical sealing.

Studies and reviews in packaging science and polymer materials consistently highlight PTFE as one of the most chemically inert and thermally durable polymers, making it well-suited for specialized sealing applications. When combined with a foam backing, PTFE-based composites not only improve sealing performance but also extend container life by preventing leaks and contamination. Compared to single-material liners, PTFE/foam laminates offer superior sealing reliability under mechanical stress and diverse environmental conditions.

Applications of PTFE/PE Composite Film

- Food and Beverage: Safe for beverages, flavorings, and consumables requiring tight closures and compliance with regulatory standards.

- Pharmaceutical and Biotech: Ideal for high-purity water storage, diagnostic reagents, and liquid formulations where sterility and chemical resistance are essential.

- Industrial and Household Chemicals: Effective for sealing acidic, alkaline, or solvent-based chemicals, ensuring product safety and user confidence.

| Model Name | Film Thickness mm(mil) | Foam Thickness mm(mil) | Peel Adhesion g/cm(oz/in) | Color | Description |

|---|---|---|---|---|---|

| ESLAM CSS1 | 0.06(2.5) | 1.3(52) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

| ESLAM CSS2 | 0.13(5) | 1.0(40) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

| ESLAM CSS3 | 0.13(5) | 1.3(52) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

| ESLAM CSS4 | 0.25(10) | 1.0(40) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

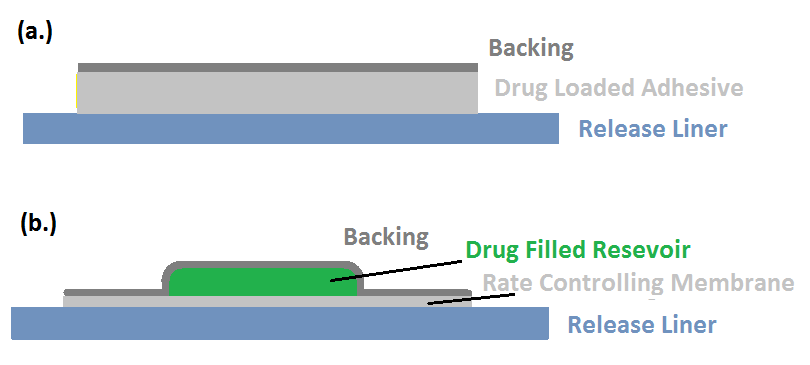

ESONE high performance films is the medical release film for skin mounted devices in pharmaceutical and medical applications.

Our films are all produced in compliance with US FDA regulations in ISO 9001-2010 environments, due to the high purity property, our liners is designed for class 1000 clean room and ESONE has more than 20 years of experience in developing custom solutions for the medical applications

Medical release liner is the important component in medical devices, transdermal drug delivery system, advanced wound care dressing and other pharmaceutical packaging product.

ESONE release liner can provide continuously release performance in the end use application while keeping increasingly stringent performance and regulatory in quality, purity and cleanliness.

Get Social