Release Films – composite process materials

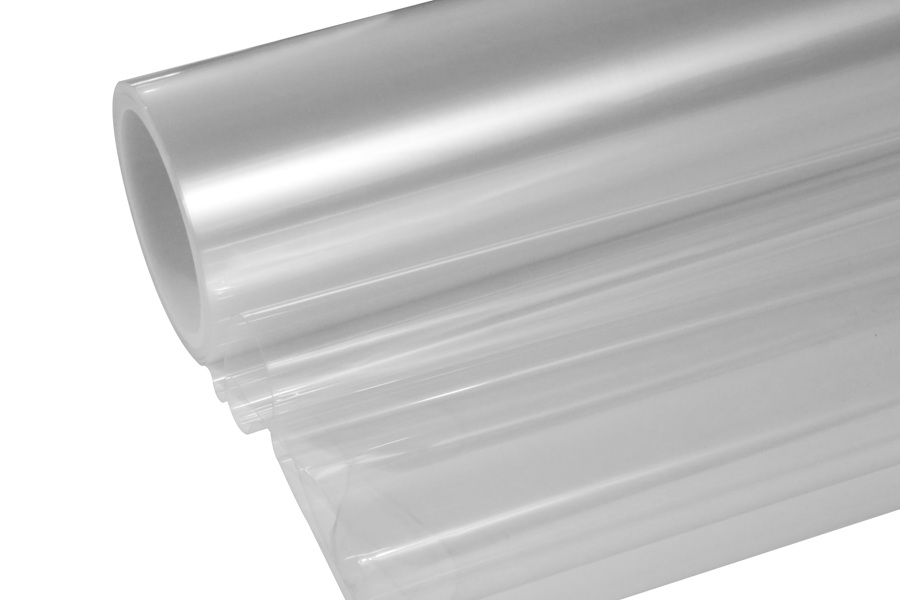

ESONE manufactures release films made from fluoropolymers specifically designed for high-temperature applications. This includes extruded fluoropolymer films (ETFE/FEP/PFA films) and PTFE casting films. Our films can be customized with various perforation patterns to accommodate both low and high venting, as well as low and high resin bleed.

Engineered for use in prepreg compaction and curing processes, our release films ensure optimal performance and reliability in demanding aerospace environments. Whether you require precise venting capabilities or effective resin management, our products are tailored to meet your specific needs.

OEM Service & Core Products

ESONE is an OEM supplier for well-known aerospace composite brands. They are long-established supplier to aircraft manufacturers worldwide.

We focus on the following four types of release films

ETFE (Ethylene Tetrafluoroethylene) Film:

Used as a replacement for Airtech’s Wrightlon 5200.

- Color Options: Available in red, blue, and yellow.

- Easy Release: Releases easily from most resin systems.

- Exceptional Elongation: Conforms to complex shapes and curvatures.

- Glossy Finish: Provides a glossy finish when applied directly to the laminate.

- High-Temperature Resistance: Withstands cure temperatures up to 500°F(260°C), the continuous working temperature is 330℉(165°C).

FEP (Fluorinated Ethylene Propylene) Film:

Used as a replacement for Airtech’s A4000.

- Color Options: Available in red, blue, violet and others.

- Easy Release: Releases smoothly from most resin systems.

- Glossy Finish: Delivers a glossy finish when removed from the laminate

- Exceptional Elongation: Easily conforms to complex shapes and curvatures.

- High-Temperature Resistance: Capable of withstanding temperatures up to 500°F (260°C), the continuous working temperature is 400℉(205°C)

PFA (Perfluoroalkoxy Alkane) Film:

- Effortless Release: Easily separates from most resin systems without difficulty.

- Glossy Surface Finish: Leaves a glossy finish on the laminate upon removal.

- Flexible Conformability: Exceptional elongation allows the film to adapt to intricate shapes and curves.

- Continuous Operating Temperature: Suitable for continuous use at temperatures up to 500°F (260°C)

- High-Temperature Capability: Withstands temperatures up to 581°F (305°C) for demanding applications.

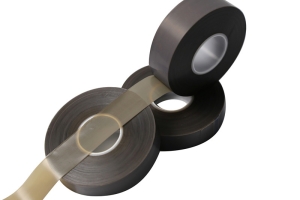

PTFE (Polytetrafluoroethylene) Casting Film:

ESONE’s PTFE Casting Film is crafted entirely from pure PTFE (Polytetrafluoroethylene) using a cast manufacturing method. This film can be produced as either a multi-layered or single-layer film, making it versatile for a wide range of applications. It is specifically engineered to withstand exposure to chemicals, heat, and mechanical stress, where low friction properties are essential. This makes it particularly suitable for environments where gases or corrosive liquids may be present, especially at elevated temperatures.

PTFE Casting film can continuously work at 600℉(316℃), maximum resistant to 620℉(327℃)

Get Social