Release Fabrics & Peel Ply & bleeders – composite process materials

ESONE offers a range of release fabrics & peel ply & bleeders, including:

- Porous PTFE Coated Fiberglass Fabric: Contains a low level of PTFE, providing higher porosity than standard PTFE coated fabrics. This allows air and excess resin to pass through, making it ideal for use as a bleeder cloth and release sheet. It is also named as Vacuum Bagging Bleeder Cloths, Bleeder Cloth, Peel ply and others.

- PTFE Open Mesh Fabrics: It is also known as Breathers & Bleeders. Due to its non-stick surface and open mesh design, this fabric allows for easy vacuum release, facilitating efficient molding processes.

- Non-Porous PTFE Coated Fabrics: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

OEM Service & Core Products

ESONE is an OEM supplier for well-known aerospace composite brands. They are long-established supplier to aircraft manufacturers worldwide.

We focus on the following three types of release fabrics & peel ply.

Product

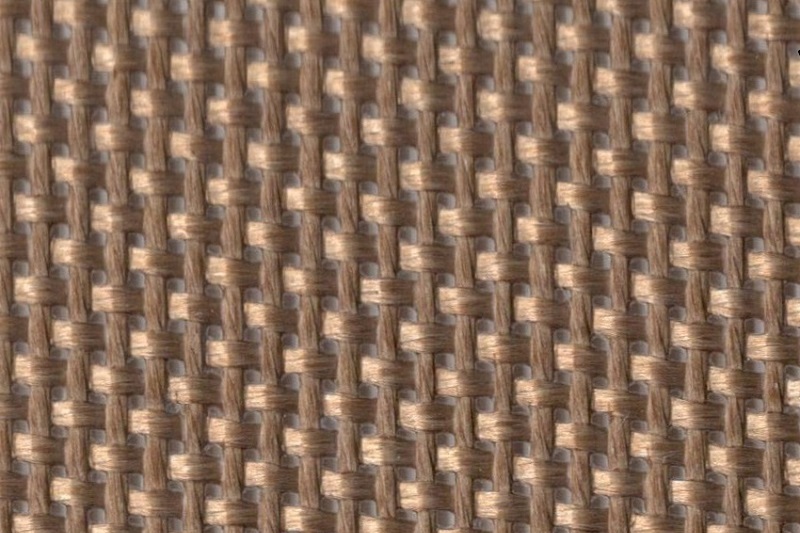

ESONE Release Fabrics & Peel Ply are crafted from PTFE coated fiberglass fabric with a low PTFE content, providing higher porosity than standard PTFE fabrics. This allows air and excess resin to pass through effectively, ensuring optimal performance.

Featuring excellent non-stick properties, these fabrics prevent adhesion, enabling easy release and maintaining clean surfaces. They serve dual purposes as both release sheets and bleeder cloths (peel ply) in the manufacturing of aircraft composites. Applications include satcom and weather radomes, helicopter rotor blades, and structural components like wings, tail sections, and fuselage parts.

Porous PTFE coated Fiberglass Fabric

PTFE Coated Fiberglass Fabric YS9006P

Used as a replacement for Aritech Release Ease 234 TFP.

- Glossy Finish: Delivers a glossy finish when removed from the laminate

- Non stick surface: Preventing resins and other materials from sticking, ensures easy release and keeps surfaces clean.

- Porous Products: These allow excess resin, volatiles, and trapped air to escape into the breather during the curing process.

- High-Temperature Resistance: Capable of withstanding temperatures up to 550°F (288°C), the continuous working temperature is 500℉(260°C)

PTFE Coated Fiberglass Fabric YS9007P

Used as a replacement for Aritech Release Ease 234 TFNP.

- Glossy Finish: Delivers a glossy finish when removed from the laminate

- Non stick surface: Preventing resins and other materials from sticking, ensures easy release and keeps surfaces clean.

- Porous Products: These allow excess resin, volatiles, and trapped air to escape into the breather during the curing process.

- High-Temperature Resistance: Capable of withstanding temperatures up to 550°F (288°C), the continuous working temperature is 500℉(260°C)

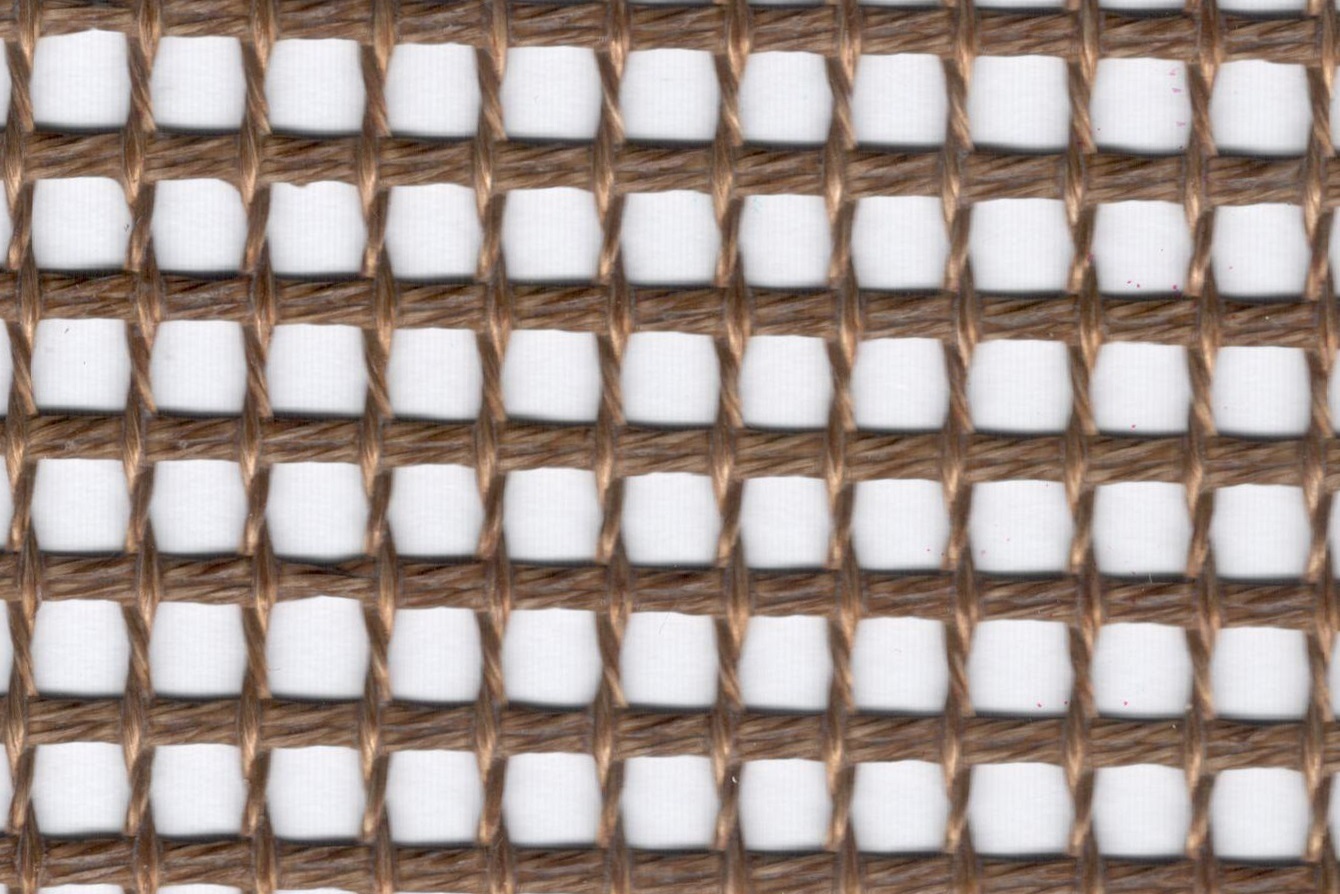

PTFE Open Mesh Fabrics, also known as Breathers & Bleeders, feature a non-stick surface and an open mesh design that allows for easy vacuum release, facilitating efficient molding processes. Available in various mesh sizes such as 1×1 and 4×4, these fabrics are ideal for applications requiring airflow and drainage.

PTFE Breathers Mesh Fabric YS6001S

Used as a replacement for Aritech TFG 660 P2.

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Open Mesh Design: The non-stick 1x1mm mesh allows for easy vacuum release, facilitating efficient molding processes.

PTFE Breathers Mesh Fabric YS6008

Used as a replacement for Aritech TFG 950 P2.

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Open Mesh Design: The non-stick 4x4mm mesh allows for easy vacuum release, facilitating efficient molding processes.

Non-Porous PTFE Coated Fabrics are engineered for applications that require a solid barrier to prevent resin penetration while ensuring easy part release. These fabrics provide excellent chemical resistance and thermal stability, making them suitable for use in harsh environments. They are often used in composite manufacturing and other industries where maintaining a clean surface is crucial.

Available in various thicknesses, including 0.08mm, 0.13mm, 0.15mm, and 0.25mm, these fabrics can be selected based on the specific requirements of the application, offering flexibility and reliability in performance. Their non-stick properties enhance productivity by reducing cleanup and maintenance time.

PTFE Non-porous Coated Fabric YS9008

0.08mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

PTFE Non-porous Coated Fabric YS9013

0.13mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

PTFE Non-porous Coated Fabric YS9015

0.15mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

PTFE Non-porous Coated Fabric YS9025

0.25mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

Get Social