PTFE Silicone Composite Films for Pharmaceutical Microbial Testing

PTFE Silicone Composite Films

In pharmaceutical research and production, accurate microbial testing and reliable gas analysis are critical for product quality and regulatory compliance. Traditional Petri dish covers can present challenges: liquid culture media may leak, dead cells can adhere to instruments, and sensors may become contaminated during oxygen or carbon dioxide monitoring.

To address these challenges, ESONE PTFE Silicone composite films provide a high-performance solution for covering microbial culture plates while enabling precise gas detection.

How It Works

- Ultra thin PTFE Layer

- Non-stick surface: The ultra-low surface energy of PTFE makes it inherently resistant to bacterial adhesion and biofilm formation, reducing contamination risks.

- Gas permeability: Ultra-thin PTFE film allows oxygen, carbon dioxide, and other gases to diffuse freely, while blocking liquid media and microorganisms.

- Chemical inertness: Completely non-reactive with pharmaceutical formulations and culture media, ensuring reliable test conditions.

- Silicone Rubber Layer

- Mechanical strength: Provides structural support, ensuring the composite film is easy to handle and securely seals onto culture dishes.

- Elastic sealing: Adapts to lids, dish rims, or analytical instruments, maintaining tight containment during testing.

- Light-blocking property: The black silicone is opaque, ensuring that the petri dishes are not affected by light exposure.

Key Advantages of PTFE Silicone Composite Films

- Accurate gas detection: Enables continuous and non-interfering monitoring of O₂ and CO₂ concentration in cultures.

- Enhanced contamination control: Prevents liquid leakage and bacterial adherence to sensors, preserving measurement integrity.

- Reliable sealing performance: Gas-permeable yet liquid-tight, providing dual protection in sensitive applications.

- Extended sensor life: Reduces fouling and maintenance caused by microbial residues.

Applications of PTFE film laminated silicone

- Microbial culture studies in pharmaceutical laboratories

- In-situ oxygen and carbon dioxide monitoring in drug testing

- Bioprocess control and fermentation systems

- Barrier films for packaging and drug delivery safety

| Model Name | Film Thickness um(mil) | Silicone Thickness um(mil) | Silicone Hardness Shore A | Color | Description |

|---|---|---|---|---|---|

| ESLAM MT1 | 4(0.15) | 30(1.2) | 30, 40 | Black | PTFE Film/Silicone Rubber |

| ESLAM MT2 | 4(0.15) | 50(2.5) | 30, 40 | Black | PTFE Film/Silicone Rubber |

| ESLAM MT3 | 10(0.4) | 50(2.5) | 30, 40 | Black | PTFE Film/Silicone Rubber |

| ESLAM MT4 | 15(0.6) | 75(3) | 30, 40 | Black | PTFE Film/Silicone Rubber |

Related Document

PTFE Silicone composite Film (TDS)

Ultra thin polytetrafluoroethylene (PTFE) film laminated with Silicone composite film for Pharmaceutical Microbial Testing

PDF| 294kb

PTFE Silicone Septa (TDS)

ESONE PTFE/Silicone composite septa are high-performance sealing materials specifically developed to meet these stringent requirements.

PDF| 301kb

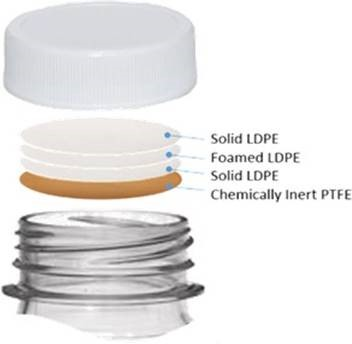

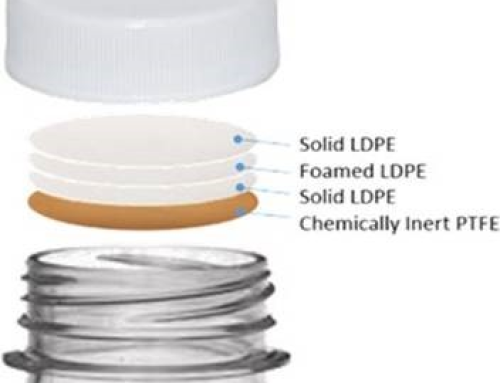

PTFE PE composite Cap Liner (TDS)

Combining polytetrafluoroethylene (PTFE) with the compressibility of polyethylene (PE) foam for making high-performance cap and container sealing Material

PDF| 333kb

Leave A Comment