THV Film

THV Film

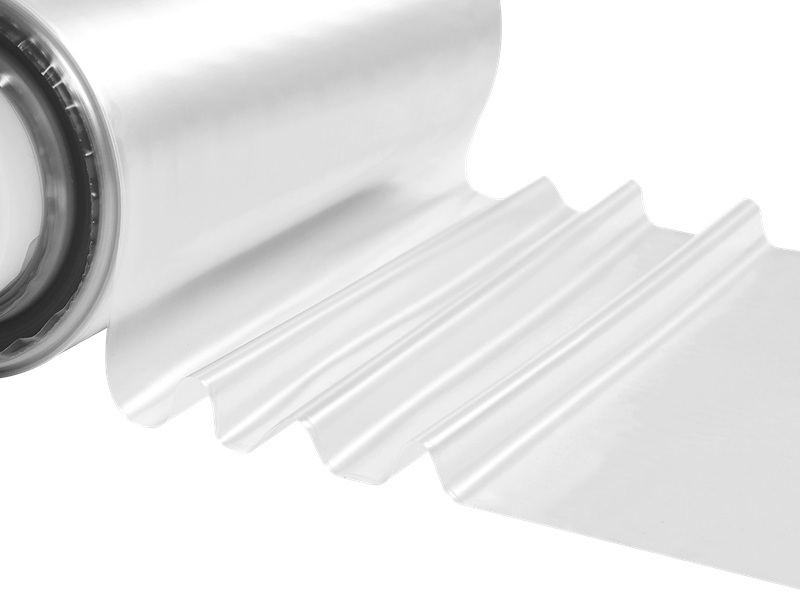

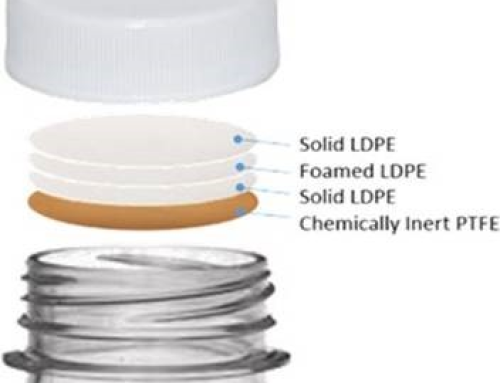

ESONE’s THV (Tetrafluoroethylene-Hexafluoropropylene-Vinylidene fluoride) Fluorothermoplastic, a polymer made from tetrafluoroethylene, hexafluoropropylene, and vinylidene fluoride, offers unique advantages such as bonding capabilities with elastomers and hydrocarbon-based plastics, along with flexibility and optical clarity. ESONE THV films, produced via melt extrusion casting from THV resin, exhibit exceptional performance characteristics, including low processing temperatures and excellent flexibility. These films can be heat-sealed, thermoformed, and laminated to various substrates, making them ideal for multilayer hoses, tubes, sheets, and films.

Advantages of THV Foil

- Very high optical clarity and light transmission

- Outstanding flexibility compared to other fluoroplastics

- Good weatherability and UV stability

- Flame retardant and good dielectric properties

- Excellent chemical and permeation resistance

- Bondable to itself and other substrates for multilayer constructions

- Low processing temperatures for co-processing with olefinic plastics and hydrocarbon elastomers

Specification of THV Film

- Standard Thicknesses: Available in 100um, 150um and 250um (0.004’’, 0.006’’ and 0.010’’), other thicknesses available upon request

- Standard Width: 300mm (11.8’’) and 1,600mm (63’’), custom slit widths available upon request

- Standard Color: Clear/natural, with custom colors available upon request

- Surface Treatment: Bondable, chemically etching, plasma-treated surfaces available upon request

Applications of THV Film

| THV Film | ||

|---|---|---|

| General Properties | Test Method | |

| Specific Gravity | ASTM D792 | 1.98 |

| Area Yield m²/kg/um (ft²/lb/mil) | 782 (97) | |

| Flammability | UL-94 | V-0 |

| Water Absoption % | <0.01 | |

| Standard width mm(in) | Max 1,600mm (63 inches) Any slit width is available | |

| Thickness Available um(mil) | 100, 150 and 250 (4, 6 and 10) | |

| Colors | Clear | |

| Mechanical Properties | ||

| Tensile Strength MPa(psi) | ASTM D882 | 30(4,500) |

| Elongation at Break % | ASTM D882 | 600 |

| Tensile Modulus MPa(psi) | ASTM D882 | 210(30,000) |

| Folding Endurance (MIT) cycles | ASTM D2176 | >100,000 |

| Thermal Properties | ||

| Continuous Use Temp ℃(℉) | UL-746B | 120(250) |

| Melt Point ℃(℉) | ASTM D3418 | 165(330) |

| Electrical Properties | ||

| Dielectric Strength kv/mm(volts/mil) | ASTM D149 | 60(1,500) |

| Dielectric Contant 1kHz | ASTM D150 | 4.8 |

| Optical Properties | ||

| Refractive Index | ASTM D542 | 1.36 |

| Solar Transmission % | ASTM E424 | 95 |

| Haze (4 mil (100 µm) film) % | ASTM E424 | 1 |

| Surface Treatments Available | ||

| Chemical Etching | Available | |

| Plasma Treatment | Available | |

| Applications | ||

| Composite Molding Process: Release Films | x | |

| Chemical Process | √ | |

| Electrical / Electronics | √ | |

| Medical | √ | |

| Optical / Photovoltaics | √ | |

| Protective / Decorative | √ | |

Related Document

THV Film (TDS)

ESONE THV Fluoropolymer Film is produced from Tetrafluoroethylene-Hexafluoropropylene-Vinylidene fluoride resin.

PDF| 367kb

Leave A Comment