PTFE PE Composite Film: High-Performance Cap and Container Sealing Solutions

In critical packaging applications, where integrity, safety, and reliability are paramount, sealing materials must withstand chemical exposure, extreme temperatures, and repeated stress. ESONE PTFE/PE Composite Film, particularly the PTFE/LDPE laminated series, are engineered to deliver outstanding performance in these demanding environments. By combining the superior chemical resistance of polytetrafluoroethylene (PTFE) with the compressibility of polyethylene (PE) foam, these laminates provide a dependable sealing solution for pharmaceutical, food, beverage, and industrial markets.

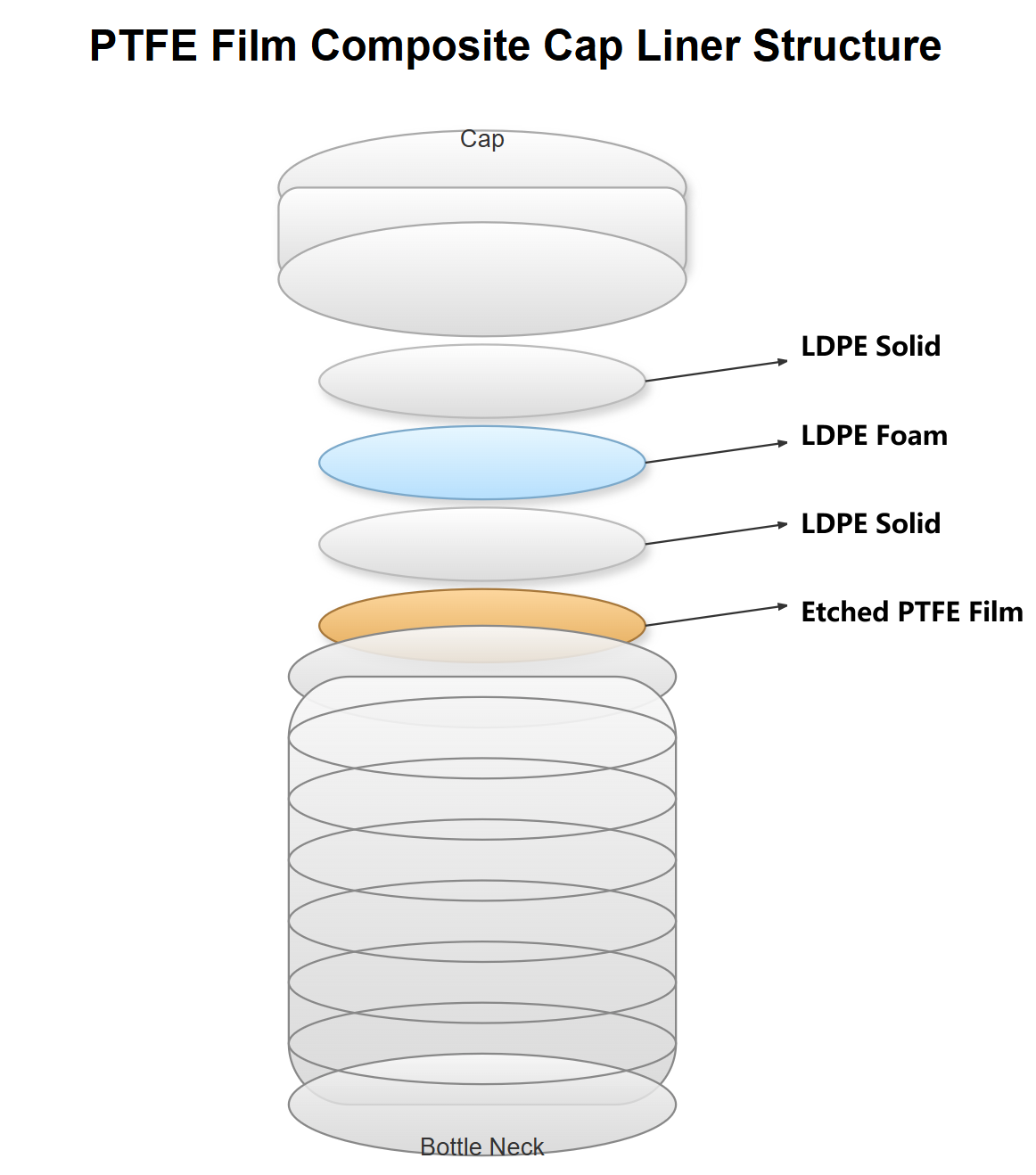

Product Structure of PTFE PE Composite Foam

The PTFE/PE laminated series consists of a skived PTFE film laminated to PE foam and solid PE backings, available in a range of thicknesses.

This dual-layer design leverages the inert and durable characteristics of PTFE film with the cushioning properties of a foam backing to ensure both chemical protection and mechanical sealing.

Studies and reviews in packaging science and polymer materials consistently highlight PTFE as one of the most chemically inert and thermally durable polymers, making it well-suited for specialized sealing applications. When combined with a foam backing, PTFE-based composites not only improve sealing performance but also extend container life by preventing leaks and contamination. Compared to single-material liners, PTFE/foam laminates offer superior sealing reliability under mechanical stress and diverse environmental conditions.

Applications of PTFE/PE Composite Film

- Food and Beverage: Safe for beverages, flavorings, and consumables requiring tight closures and compliance with regulatory standards.

- Pharmaceutical and Biotech: Ideal for high-purity water storage, diagnostic reagents, and liquid formulations where sterility and chemical resistance are essential.

- Industrial and Household Chemicals: Effective for sealing acidic, alkaline, or solvent-based chemicals, ensuring product safety and user confidence.

Key Advantages of PTFE PE Composite

- Thermal Stability: The laminates retain sealing integrity under fluctuating temperatures, making them suitable for sterilization cycles and hot or cold storage conditions.

- Chemical Resistance: PTFE is renowned for its non-reactivity with a wide spectrum of acids, bases, solvents, and high-purity water. This ensures long-lasting compatibility for sensitive formulations.

- Sterilization Compatibility: ESONE products can be sterilized using Ethylene Oxide (EtO) or autoclave methods, supporting pharmaceutical and biological applications.

- Regulatory Compliance: Selected versions comply with EU 10/2011 and FDA 21 CFR 177.1550 standards, making them suitable for direct food and drug contact. All laminates are free from PFOA.

- Compression and Torsional Sealing: The foam backing provides excellent compression recovery, enabling tight, consistent seals in threaded closures.

TDS of PTFE Composite Film with LDPE Foam

| Model Name | Film Thickness mm(mil) | Foam Thickness mm(mil) | Peel Adhesion g/cm(oz/in) | Color | Description |

|---|---|---|---|---|---|

| ESLAM CSS1 | 0.06(2.5) | 1.3(52) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

| ESLAM CSS2 | 0.13(5) | 1.0(40) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

| ESLAM CSS3 | 0.13(5) | 1.3(52) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

| ESLAM CSS4 | 0.25(10) | 1.0(40) | 500 (45) | White | PTFE Film/LDPE Solid/LDPE Foam |

Related Document

PTFE PE composite Cap Liner (TDS)

Combining polytetrafluoroethylene (PTFE) with the compressibility of polyethylene (PE) foam for making high-performance cap and container sealing Material

PDF| 333kb

PTFE Silicone Septa (TDS)

ESONE PTFE/Silicone composite septa are high-performance sealing materials specifically developed to meet these stringent requirements.

PDF| 301kb

PTFE Silicone composite Film (TDS)

Ultra thin polytetrafluoroethylene (PTFE) film laminated with Silicone composite film for Pharmaceutical Microbial Testing

PDF| 294kb

Leave A Comment