PTFE Silicone Septa Vial Sealing Materials

PTFE Silicone Septa

In pharmaceutical, life science, and analytical laboratories, vial sealing materials play a critical role in ensuring sample integrity and maintaining the accuracy of experimental results. ESONE PTFE/Silicone composite septa are high-performance sealing materials specifically developed to meet these stringent requirements.

Key Features of PTFE Silicone Septa

- Excellent resealability: Maintains a tight seal even after multiple punctures.

- High PTFE/silicone bond strength: Long-term stability without delamination.

- Broad temperature resistance: -40 °C to +220 °C(-40 °F 到 428 °F), suitable for cold-chain and high-temperature environments.

- Outstanding chemical resistance: Compatible with a wide range of solvents and reagents.

- Consistent silicone hardness (durometer): Ensures controlled needle penetration and enhances product durability.

Structure and Working Principle of PTFE Silicone Laminates

ESONE septa feature a two-layer composite construction:

- PTFE film layer: Provides excellent chemical inertness and outstanding resistance to a wide range of solvents and reagents. By creating a highly stable barrier, the PTFE surface prevents leaching of impurities and protects sensitive samples from degradation. This ensures that the vial contents remain uncontaminated and chemically intact, making it particularly valuable for critical applications such as pharmaceutical formulations, chromatography, and high-purity analytical testing.

For PTFE, the characteristic peaks in the approximately 1150 and 1205 cm-1

- Silicone elastomer layer: Delivers outstanding elasticity and resealability. After syringe penetration, the septa reseal immediately, maintaining vial integrity.

This unique structure offers a robust chemical barrier while enabling reliable resealing during multiple sampling operations.

For Silicone, typical FTIR spectra corresponding to a C-H band for Si-CH3 at 1255 cm-1, Si-O-Si band at 1092 and 1023 cm-1, Si-C from Si-CH3 at 864 and C-H (CH3) at 800 cm-1.

Key Features of PTFE Silicone Septa

- Excellent resealability: Maintains a tight seal even after multiple punctures.

- High PTFE/silicone bond strength: Long-term stability without delamination.

- Broad temperature resistance: -40 °C to +220 °C(-40 °F 到 428 °F), suitable for cold-chain and high-temperature environments.

- Outstanding chemical resistance: Compatible with a wide range of solvents and reagents.

- Consistent silicone hardness (durometer): Ensures controlled needle penetration and enhances product durability.

Applications of PTFE silicone Rubber Septa

- Pharmaceutical and life sciences: Secure vial sealing to prevent external contamination.

- Chromatographic research (GC, HPLC, MS): Low background noise and extractables, ensuring accurate test results.

- Scientific and industrial experiments: Suitable for environments demanding purity and high chemical resistance.

TDS of PTFE/Silicone Septa Sealing Material

| Model Name | Film Thickness mm(mil) | Silicone Thickness mm(mil) | Tensile Strength MPa | Silicone Hardness Shore A | Color | Description |

|---|---|---|---|---|---|---|

| ESLAM SEP1 | 0.075(3) | 0.5(20) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

| ESLAM SEP2 | 0.075(3) | 1.0(40) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

| ESLAM SEP3 | 0.13(5) | 1.0(40) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

| ESLAM SEP4 | 0.13(5) | 3.0(120) | 6 | 30, 40 | Red/White | PTFE Film/Silicone Rubber |

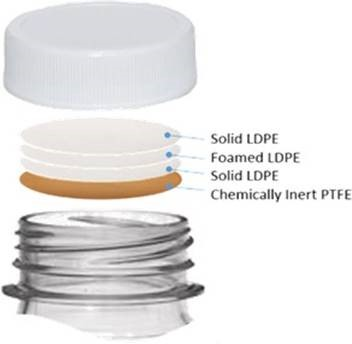

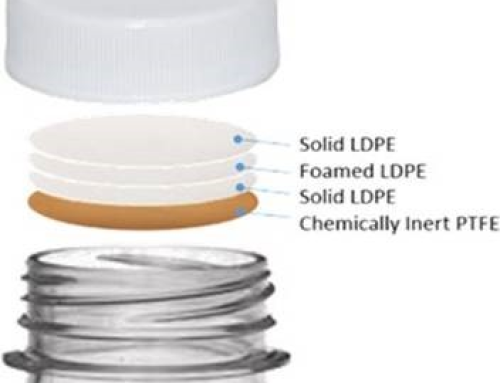

ESONE cap liner can also use PTFE film laminated with PE Foam

TDS of PTFE/PE Foam Septa Sealing Material

| Products | PTFE Thickness (mm) | Total Thickness (mm) | Max Width (mm) | Foam Density g/cc |

|---|---|---|---|---|

| PTFE Film + PE Foam + PTFE Film | 0.05-0.13 | 1-3 | 1000 | 0.3-0.6 |

| PTFE Film + PE Foam + PE Film | 0.05-0.13 | 1-3 | 1000 | 0.3-0.6 |

Related Document

PTFE Silicone Septa (TDS)

ESONE PTFE/Silicone composite septa are high-performance sealing materials specifically developed to meet these stringent requirements.

PDF| 301kb

PTFE PE composite Cap Liner (TDS)

Combining polytetrafluoroethylene (PTFE) with the compressibility of polyethylene (PE) foam for making high-performance cap and container sealing Material

PDF| 333kb

PTFE Silicone composite Film (TDS)

Ultra thin polytetrafluoroethylene (PTFE) film laminated with Silicone composite film for Pharmaceutical Microbial Testing

PDF| 294kb

Leave A Comment