PTFE coated Kevlar Belt Black in Magnet Production

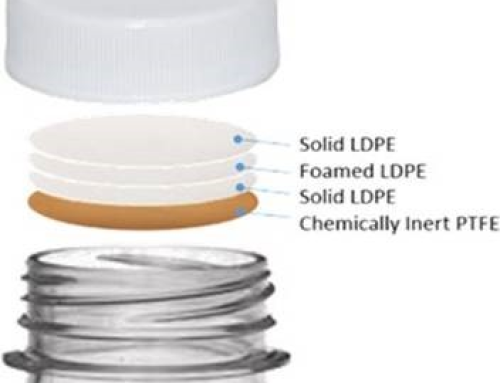

PTFE coated Kevlar belt is engineered by applying a PTFE coating onto a high‑strength aramid (Kevlar) base fabric. The Kevlar base provides exceptional tensile strength, abrasion resistance, and dimensional stability, while the PTFE surface adds a smooth, non‑stick layer with excellent chemical and moisture resistance.

For specific industrial needs, the PTFE surface can also be manufactured in black antistatic form, which helps reduce static buildup and enhances safety in powder handling environments.

Key Characteristics of PTFE Aramid Fabric

- High Tensile Strength – Kevlar ensures excellent load‑bearing capacity and resistance to stretching, ideal for demanding conveyor applications.

- Non‑Stick Surface – PTFE provides a low‑friction, easy‑release surface that prevents fine powders from adhering.

- Moisture and Chemical Resistance – Suitable for humid or reactive processing environments, much better than fiberglass.

- Wear Resistance – Withstands continuous abrasion and high‑duty cycles.

- Optional Black Antistatic Finish – Provides static control in sensitive powder processing applications.

Application in the Magnet Industry

In the production of permanent magnets, PTFE‑coated Kevlar fabric is widely used to manufacture conveyor belts for magnetic separation processes.

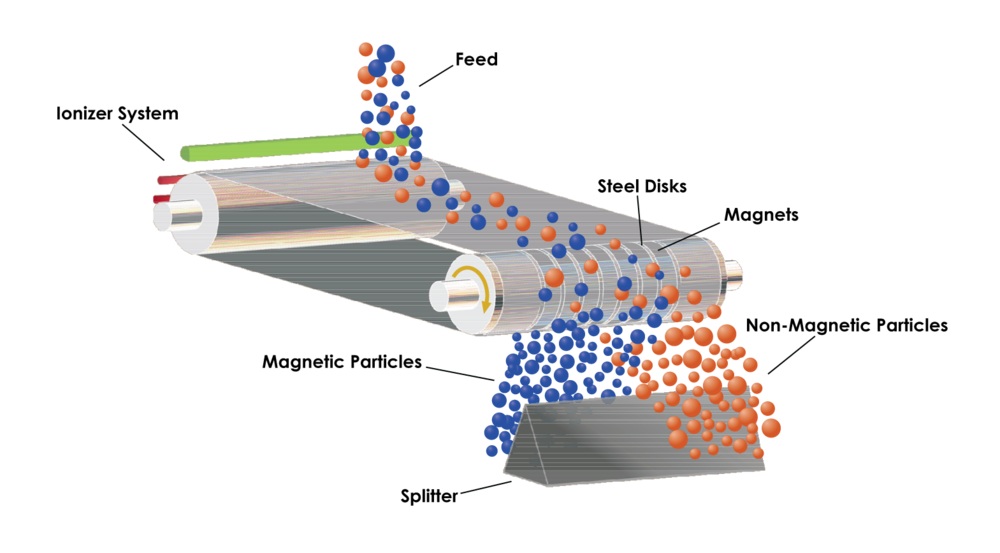

During magnetic separation, mixed powders containing both magnetic and non‑magnetic particles are transported across magnetic rollers. The black antistatic PTFE‑coated aramid conveyor belts provide:

- A durable, high‑strength base to carry fine powders without stretching.

- A non‑magnetic, PTFE surface that does not interfere with magnetic fields.

- An antistatic finish to minimize static buildup during fine powder handling.

- An easy‑to‑clean, non‑stick surface that prevents powder accumulation and cross‑contamination.

Why PTFE Coated Kevlar Belt?

In the magnetic separation stage:

- Mixed powder feed falls onto the moving conveyor belt.

- As the belt carries the material across magnetic rollers, magnetic particles adhere to the drum while non‑magnetic particles fall off naturally.

- The PTFE‑coated Kevlar belt provides a smooth, stable, and neutral transport surface, ensuring precise particle separation.

- Its non‑stick property prevents powder build‑up around the drum and splitter, enhancing both efficiency and consistency.

The magnet manufacturing process demands materials that can perform reliably under stringent mechanical, thermal, and magnetic conditions. PTFE coated Kevlar belt meet these requirements by delivering strength, durability, non‑magnetic neutrality, and superior non‑stick properties. For manufacturers looking to optimize separation efficiency and overall process stability, these belts present a proven and cost‑effective solution.

| Product | Product Category | Coating |

|---|---|---|

| PTFE ARAMID FABRIC | KEVLAR SERIES | PTFE |

| PTFE Fabric Kevlar Series | |||||

|---|---|---|---|---|---|

| Style | Standard Width(mm) Please ask for other widths | Normal Thickness (mm) | Weight (g/m2) | PTFE Content (%) | Tensile Strength Warp/Fill (N/cm) |

| YS9013AK | 1000, 1250, 1500 | 0.13mm | 200 | 67 | 360/200 |

| YS9013BK | 1000, 1250, 1500 | 0.13mm | 200 | 67 | 360/200 |

| YS9019AK | 1000, 1250 | 0.19mm | 320 | 64 | 590/550 |

| YS9019BK | 1000, 1250 | 0.19mm | 320 | 64 | 590/550 |

| YS9028AK | 1400 | 0.28mm | 400 | 60 | 760/710 |

| YS9040AK | 1400 | 0.40mm | 660 | 60 | 1040/1010 |

| YS9050AK | 1400 | 0.50mm | 760 | 60 | 1160/1130 |

Leave A Comment