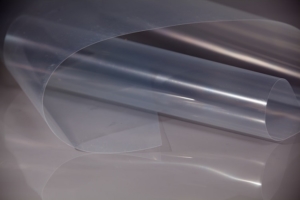

Skived PTFE Film

Premium PTFE Skived Film is skived from the top quality virgin PTFE resin. This skived film is engineered to meet the request of demanding electrical, mechanical, chemical and medical applications.

BENEFITS:

- Virgin PTFE film

- Non-stick film with a low coefficient of friction

- Excellent service and availability

- Continuously working below 500°F

- Outstanding electrical insulation properties

- Semi-conductive fillers are available

| PTFE Film | |

|---|---|

| Thickness Range | 0.5 mil – 125 mil |

| Density | 2.14 – 2.19 g/cm3 |

| Elongation | 300 % |

| Tensile Strength | 4,000 psi |

| Dielectric Strength | 1,680 volts/mil |

| Color | Natural |

| Yield | 88.6 ft²/lb per mil |

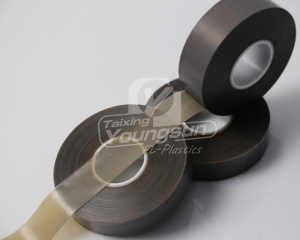

PTFE Adhesive Film

| Product | Product Category | Coating |

|---|---|---|

| PTFE SKIVED FILM ADHESIVE TAPE | PTFE FILM ADHESIVE SERIES | SILICONE PSA |

| PTFE Skived Film Adhesive Tape Series | |||||

|---|---|---|---|---|---|

| Style | Standard Width(mm) Please ask for other widths | Backing Thickness (mm) | Total Thickness (mm) | Adhesion (N/cm) | Temperature Resistant (°C) |

| YS7908 | 5-500 | 0.05 | 0.08 | 2.2 | -73 to +260 |

| YS7908Y | 5-500 | 0.05 | 0.08 | 2 | -43 to +160 |

| YS7913 | 5-500 | 0.09 | 0.13 | 3.2 | -73 to +260 |

| YS7913Y | 5-500 | 0.09 | 0.13 | 3 | -43 to +160 |

| YS7918 | 5-500 | 0.14 | 0.18 | 4 | -73 to +260 |

| YS7925 | 5-1000 | 0.20 | 0.25 | 4.6 | -73 to +260 |

| YS7930 | 5-1000 | 0.25 | 0.30 | 4.8 | -73 to +260 |

| YS7950 | 5-1000 | 0.45 | 0.50 | 6 | -73 to +260 |

| YS7957 | 5-1000 | 0.52 | 0.57 | 6 | -73 to +260 |

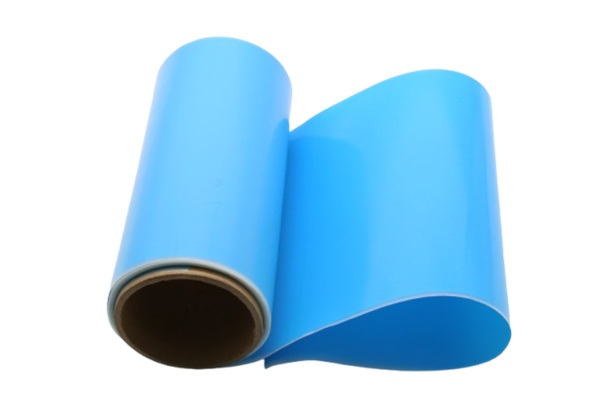

PTFE Casting Film

PTFE Casting Film is specially sintered and deposited, resulting in a very thin PTFE film which has many uniform properties that can’t be achieved by another production process.

Multi-layering produces a high performance PTFE film which is workable for the most challenging applications.

This unique process allows us to fabricate cast films ranging from 1/4 to 5 mils in thickness, meeting many agency specifications and suitable for continuous service in a wide temperature range from -320°F to +500°F.

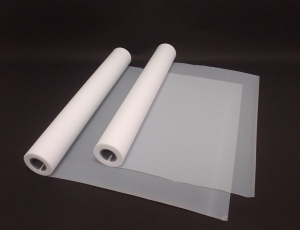

PFA Film

PFA fluoropolymer film can work continuously under temperature 260°C/500°F, the properties of PFA film is better than any melt-processable fluoropolymer film. PFA film offers better performance than PTFE film, it is transparent and can be heat sealed, thermoformed, welded, metallized, or laminated to a wide variety of materials.

PFA film has excellent dielectric strength and highest level of chemical resistance and stress crack resistance and weatherability. This film is a great solution for application which don’t need high aesthetic standards, such as heat sealed adhesive (welding tape) application.

Advantages:

- Outstanding flex life and stress

crack resistance - Heat resistance up to 500°F

- Excellent non stick surface

- Excellent electrical properties

- Excellent weatherability

- Thicknesses from 0.0005″(0.0127 mm) to .010″ (0.76 mm)

- Width up to 60″ (1,575 mm) for 0.0005″ to 0.010″

- Available in etched surface

ESONE’s UHMW tape is made from ultra-high molecular weight polyethylene (UHMH) film with a molecular weight exceeding 9 million, coated with either acrylic pressure-sensitive adhesive or rubber adhesive.

ESONE UHMW tape exhibits excellent abrasion resistance and has a low coefficient of friction, making it an ideal protection for surfaces or bearings that experience heavy wear. Additionally, ESONE UPE tape is more economical than PTFE tapes. The high-tack rubber adhesive adheres readily to most dry, clean surfaces, firmly anchoring the product in place, even in the high heat ranges noted in this data sheet.

- Self-lubricating

- Low coefficient of friction

- Powerful adhesive back

- Excellent abrasion resistance

- Superior chemical resistance

Get Social