Aerospace

ESONE fluoropolymer extruded film, casting film, PTFE film/PTFE coated fabric with or without adhesive are used in the manufacturing of aircraft composited components, such as helicopter rotor blades, satcom and weather radomes, structural component like tail sections, wings and wire harness protective insulation.

In the full range of applications, the release properties, mechanical properties and porosity of the product selected are critical to the performance of the manufacturing process and the quality of the products produced.

OEM Service & Core Products

ESONE is an OEM supplier for well-known aerospace composite brands. They are long-established supplier to aircraft manufacturers worldwide.

We focus on the following four types of materials:

Product

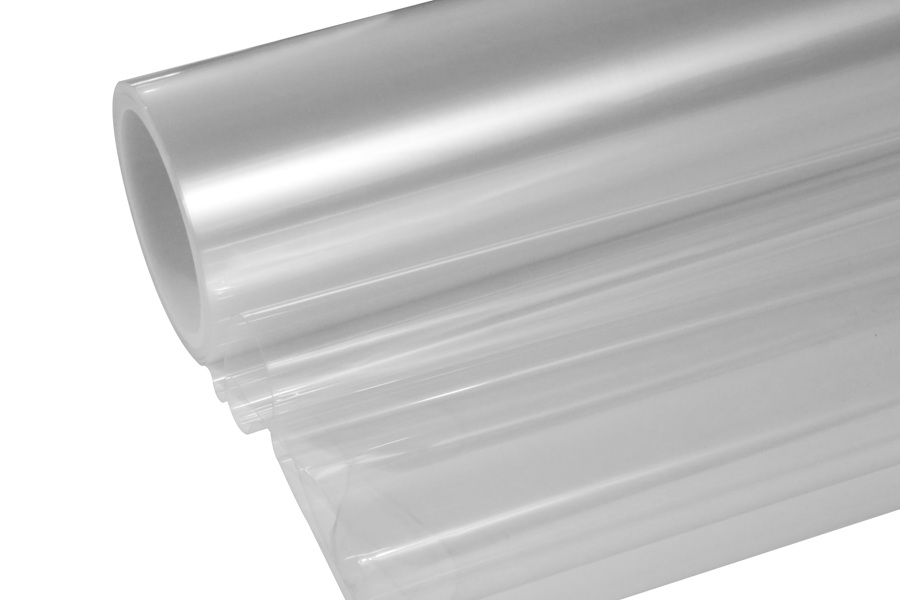

ESONE manufactures release films made from fluoropolymers designed for high-temperature applications, including extruded fluoropolymer film and PTFE casting films. These films can be customized with various perforation patterns to accommodate both low and high venting, as well as low and high resin bleed.

Our release films are specifically engineered for use in prepreg compaction and curing processes, ensuring optimal performance and reliability in demanding aerospace environments. Whether you need precise venting capabilities or effective resin management, our products are tailored to meet your requirements.

ETFE (Ethylene Tetrafluoroethylene) Film:

- Color Options: Available in red, blue, and yellow.

- Easy Release: Releases easily from most resin systems.

- Exceptional Elongation: Conforms to complex shapes and curvatures.

- Glossy Finish: Provides a glossy finish when applied directly to the laminate.

- High-Temperature Resistance: Withstands cure temperatures up to 500°F(260°C), the continuous working temperature is 330℉(165°C).

FEP (Fluorinated Ethylene Propylene) Film:

- Color Options: Available in red, blue, violet and others.

- Easy Release: Releases smoothly from most resin systems.

- Glossy Finish: Delivers a glossy finish when removed from the laminate

- Exceptional Elongation: Easily conforms to complex shapes and curvatures.

- High-Temperature Resistance: Capable of withstanding temperatures up to 500°F (260°C), the continuous working temperature is 400℉(205°C)

PFA (Perfluoroalkoxy Alkane) Film:

- Effortless Release: Easily separates from most resin systems without difficulty.

- Glossy Surface Finish: Leaves a glossy finish on the laminate upon removal.

- Flexible Conformability: Exceptional elongation allows the film to adapt to intricate shapes and curves.

- Continuous Operating Temperature: Suitable for continuous use at temperatures up to 500°F (260°C)

- High-Temperature Capability: Withstands temperatures up to 581°F (305°C) for demanding applications.

PTFE (Polytetrafluoroethylene) Casting Film:

ESONE’s PTFE Casting Film is crafted entirely from pure PTFE (Polytetrafluoroethylene) using a cast manufacturing method. This film can be produced as either a multi-layered or single-layer film, making it versatile for a wide range of applications. It is specifically engineered to withstand exposure to chemicals, heat, and mechanical stress, where low friction properties are essential. This makes it particularly suitable for environments where gases or corrosive liquids may be present, especially at elevated temperatures.

PTFE Casting film can continuously work at 600℉(316℃), maximum resistant to 620℉(327℃)

ESONE offers a range of release fabrics & peel ply & bleeders, including:

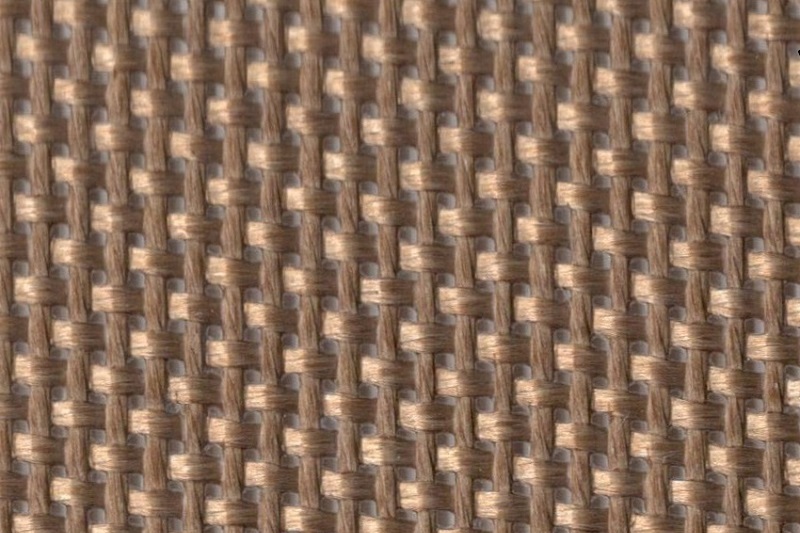

- Porous PTFE Coated Fiberglass Fabric: Contains a low level of PTFE, providing higher porosity than standard PTFE coated fabrics. This allows air and excess resin to pass through, making it ideal for use as a bleeder cloth and release sheet. It is also named as Vacuum Bagging Bleeder Cloths, Bleeder Cloth, Peel ply and others.

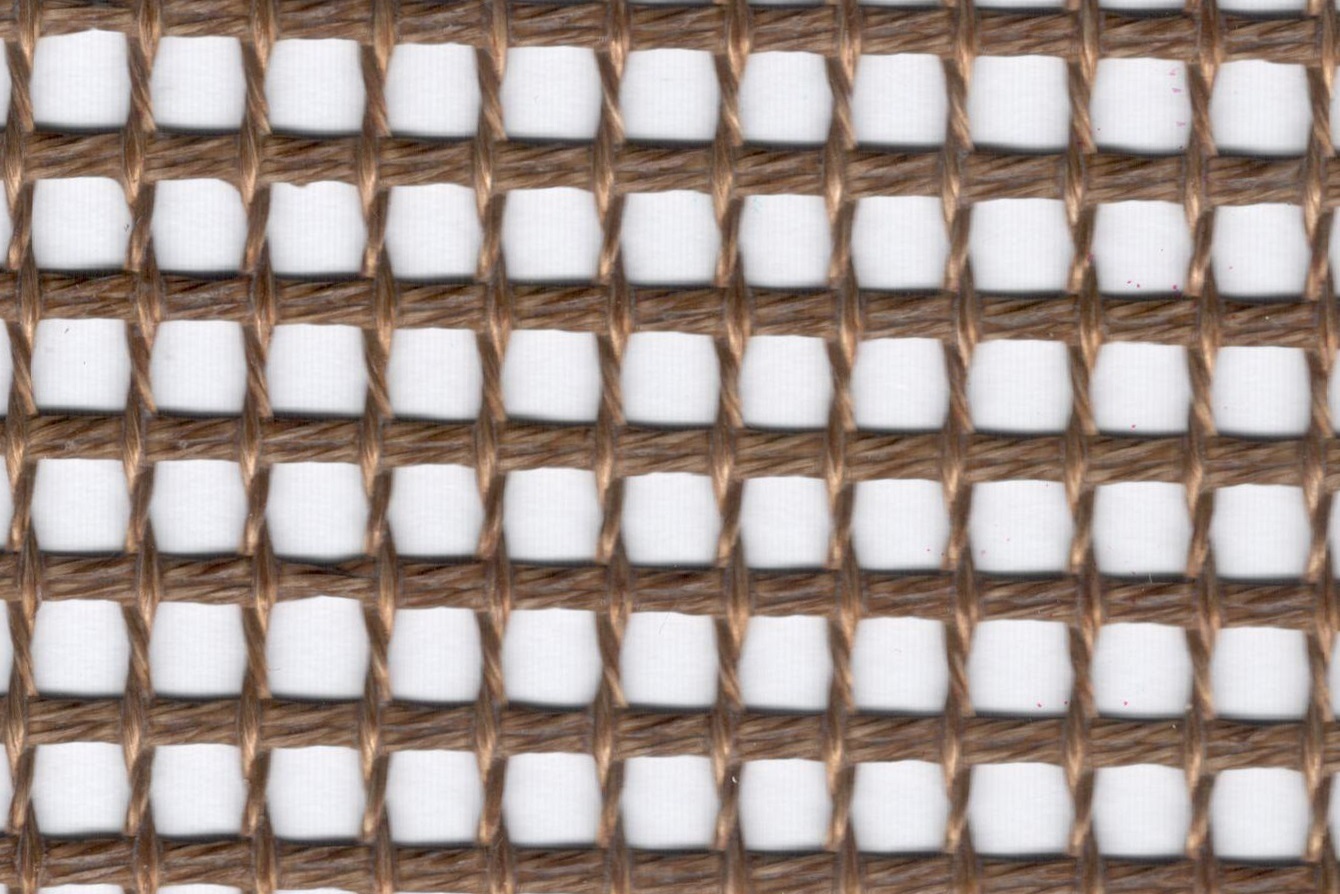

- PTFE Open Mesh Fabrics: It is also known as Breathers & Bleeders. Due to its non-stick surface and open mesh design, this fabric allows for easy vacuum release, facilitating efficient molding processes.

- Non-Porous PTFE Coated Fabrics: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

These fabrics are used in the manufacturing of aircraft composites, including Satcom and weather radomes, Helicopter rotor blades, Structural components like wings, tail sections, fuselage components and others.

Porous PTFE Fabric

Porous PTFE Coated Fiberglass Fabric YS9006P

- Glossy Finish: Delivers a glossy finish when removed from the laminate

- Non stick surface: Preventing resins and other materials from sticking, ensures easy release and keeps surfaces clean.

- Porous Products: These allow excess resin, volatiles, and trapped air to escape into the breather during the curing process.

- High-Temperature Resistance: Capable of withstanding temperatures up to 550°F (288°C), the continuous working temperature is 500℉(260°C)

Porous PTFE Coated Fiberglass Fabric YS9007P

- Glossy Finish: Delivers a glossy finish when removed from the laminate

- Non stick surface: Preventing resins and other materials from sticking, ensures easy release and keeps surfaces clean.

- Porous Products: These allow excess resin, volatiles, and trapped air to escape into the breather during the curing process.

- High-Temperature Resistance: Capable of withstanding temperatures up to 550°F (288°C), the continuous working temperature is 500℉(260°C)

PTFE Breathers Mesh Fabric YS6001S

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Open Mesh Design: The non-stick 1x1mm mesh allows for easy vacuum release, facilitating efficient molding processes.

PTFE Breathers Mesh Fabric YS6008

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Open Mesh Design: The non-stick 4x4mm mesh allows for easy vacuum release, facilitating efficient molding processes.

PTFE Non-porous Coated Fabric YS9008

0.08mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

PTFE Non-porous Coated Fabric YS9013

0.13mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

PTFE Non-porous Coated Fabric YS9015

0.15mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

PTFE Non-porous Coated Fabric YS9025

0.25mm thick PTFE coated fabric

- Heat Resistance: Capable of withstanding high temperatures.

- Chemical Resistance: Exhibits excellent resistance to a wide range of chemicals.

- Non-porous surface: Designed for applications requiring a solid barrier, preventing resin penetration while ensuring easy part release.

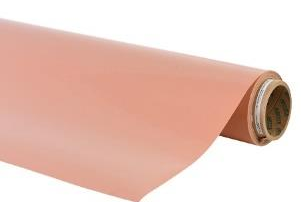

PTFE Mold Release Tape, make of woven fiberglass coated with high quality PTFE(TEFLON), and back side coated with Silicone PSA. This mold release tape has higher tensile strength than normal self adhesive PTFE fabric. In this case, ESONE adhesive tape will be easily took down after repeatedly used.

ESONE mold release adhesive fabric is used to stick the molding, for the manufacturing of aircraft composites, wind power blade composite, like satcom and weather radomes, helicopter rotor blade, structural components like wings, tail section, fuselage component and so on.

ESONE specializes in a variety of mold release tapes, including:

- PTFE Coated Fiberglass Tape

- Extruded Fluoropolymer Adhesive Tape

- PTFE Skived Adhesive Film with High Elongation

Mould Release PTFE coated fiberglass adhesive fabric YS7007AT

- Outstanding Easy Release: Features low adhesion, making it easy to peel away after use.

- Mechanical Strength: Offers excellent mechanical strength and can be reused multiple times.

- Clean Removal: Leaves no adhesive residue after peeling, ensuring a clean surface.

- Performance: Ensures reliable protection and performance for your tooling applications.

- Versatility: Suitable for use on all types of molds, press platens, caul sheets, and any surfaces in contact with resins or adhesives.

Mould Release PTFE coated fiberglass adhesive fabric YS7013AT

- Outstanding Easy Release: Features low adhesion, making it easy to peel away after use.

- Mechanical Strength: Offers excellent mechanical strength and can be reused multiple times.

- Clean Removal: Leaves no adhesive residue after peeling, ensuring a clean surface.

- Performance: Ensures reliable protection and performance for your tooling applications.

- Versatility: Suitable for use on all types of molds, press platens, caul sheets, and any surfaces in contact with resins or adhesives.

Mould Release extruded fluoropolymer adhesive tape YS7907-HM

- Clean Removal: Ensures excellent clean-up after removal, leaving no adhesive residue behind.

- Versatility: Suitable for use on all types of molds, press platens, caul sheets, and any surfaces in contact with resins or adhesives.

- Permanent Release Surface: Provides a durable release surface that lasts throughout the production cycle.

- High Temperature Resistance: Suitable for high-temperature environments without losing performance.

- Mechanical Strength: Due to its extruded design, it exhibits high strength in the extrusion direction, significantly stronger than conventional mold release tapes.

Mould Release extruded fluoropolymer adhesive tape YS7910-HM

- Clean Removal: Ensures excellent clean-up after removal, leaving no adhesive residue behind.

- Versatility: Suitable for use on all types of molds, press platens, caul sheets, and any surfaces in contact with resins or adhesives.

- Permanent Release Surface: Provides a durable release surface that lasts throughout the production cycle.

- High Temperature Resistance: Suitable for high-temperature environments without losing performance.

- Mechanical Strength: Due to its extruded design, it exhibits high strength in the extrusion direction, significantly stronger than conventional mold release tapes.

Mould Release PTFE skived adhesive tape YS7918 with high elongation

- Non-contamination: Contains no fiberglass, ensuring complete contamination-free performance.

- High Elongation: Features excellent stretchability, allowing it to conform to complex contours.

- Clean Removal: Ensures excellent clean-up after removal, leaving no adhesive residue behind.

- Versatility: Suitable for use on all types of molds, press platens, caul sheets, and any surfaces in contact with resins or adhesives.

- High Temperature Resistance: Suitable for high-temperature environments without losing performance.

ESONE Pressure Sensitive Tapes provide a cost-effective and convenient solution for protecting molds from resin flash, as well as for holding, fixing, and general-purpose applications. PTFE skived film adhesive and PTFE extruded film tapes are specifically designed to ensure effective release for all common resin types. Additionally, ESONE pressure sensitive Tapes can be supplied in pre-cut pieces, enhancing usability and efficiency in the molding process.

Pressure Sensitive Tapes Fluoropolymer extruded film tape YS7910-HM

Tapes for holding, fixing, masking, releasing and protecting

- Eye-catching Color: Bright orange, ensuring high visibility on most substrates.

- High Temperature Resistance: Suitable for high-temperature environments without losing performance.

- Mechanical Strength: Due to its extruded design, it exhibits high strength in the extrusion direction, significantly stronger than conventional mold release tapes.

Mould Release PTFE skived adhesive tape YS7908 with high elongation

- Performance: Conforms to critical contours and mold surfaces.

- Versatility: Suitable for multiple releases and covering detail mold seams.

- High Elongation: Ideal for tooling blocks and areas requiring high elongation and release.

- High Temperature Resistance: Suitable for high-temperature environments without losing performance.

Applications

PTFE coated fiberglass fabric is widely used in various aircraft composite manufacturing process, including vacuum bagging technique, open molded and hand lay-up process.

PTFE bleeder cloth and PTFE mold release tape will be used directly to the mold and product, allowing for a easy and clean release after the curing process of aircraft composite. ESONE porous PTFE fabric can ensure perfect release while maintaining the breathable property, which can allow air and volatiles to escape during production. And due to the high mechanical strength of mold release tape, ESONE adhesive fabric is reusable and provide clean release.

The applications including helicopter rotor blades, satcom, weather radomes and others

This application also use PTFE porous fabric and PTFE adhesive fabric. We customize PTFE porous fabric with balanced porosity & release property, and has high mechanical strength. For PTFE adhesive fabric, our mold release tape is easy release and has high mechanical strength, so that it can be reused many times easily.

ESONE PTFE fabric also names as heat resistant peel ply, this allows for the composite to be peeled from fabric after it is cured, and the result is a perfectly smooth surface.

Due to the low dielectric constant, low loss tangent and low interference with microwave frequencies, ESONE high performance PTFE coated fiberglass fabric is the perfect solution for radome cover for devices such as satellite terminal, portable radomes for VSAT, flexible planar radomes, Fly Away satellite communications terminals, and microwave communication antennas.

Meanwhile, ESONE PTFE coated fabric has strong mechanical strength, which is easy to install and can prevent bird’s peck.

Due to the high dielectric strength of PTFE and strong mechanical strength of glass fiber, PTFE coated fabric is the great solution for shielding of electrical cables and individual components.

What’s more, since PTFE tape or fabric offer abrasion resistant insulation and low friction surface, ESONE’s product can serve the most demanding industrial electrical needs in modern aircraft industry.

Get Social