Vacuum Bagging Bleeder Cloths, used for Aircraft composites manufacturing

Vacuum Bagging Bleeder Cloths, make of PTFE coated fiberglass fabric with low level of PTFE content, which has a higher porosity than normal PTFE coated fabric. This fabric is also named with release fabric & peel ply.

In this case, air and extra resin will be allowed for passing through the bleeder cloths. This fabric is used as release sheet and bleeder cloth, for the manufacturing of aircraft composites, including satcom and weather radomes, helicopter rotor blade, structural components like wings, tail section, fuselage component and so on.

How to use Vacuum bagging bleeder cloths

- Placement: Position the vacuum bagging bleeder cloths above the resin layer, ensuring direct contact with the resin surface.

- Function: The bleeder cloths allow excess resin to escape and facilitate the release of trapped air, ensuring optimal compaction during the curing process.

- Surface Finish: By using the bleeder cloths, you can achieve a smooth and clean surface finish for your composite products.

- Vacuum Setup: Finally, ensure proper vacuum sealing over the bleeder cloths to maintain consistent pressure throughout the curing process.

Click here to access the Porous PTFE Sheet YS9006P Used as a replacement for Release Ease 234 TFP.

Click here to access the Porous PTFE sheet YS9007PUsed as a replacement for Release Ease 234 TFNP.

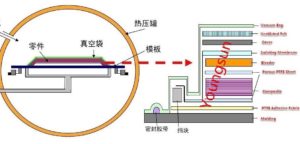

Vacuum bagging system is consist of vacuum bag, ventilated felt, cover, isolating membrane, bleeder, bleeder cloth(Porous PTFE fabric), composite, PTFE adhesive fabric and molding.

After extracting vacuum, autoclave molding will release high temperature, high pressure by adding heat compression air, for the curing and molding of the composite. And ESONE PTFE coated fabric will provide a easy and clean release after curing process, air, resin and volatile will be allowed for escaping.

The surface of composite will be excellent smooth by using Vacuum bagging bleeder cloths, and composite will be very easy to peeled off from the PTFE peel ply after cured.

Property of PTFE coated Peel Ply

★ Easy release and non stick.

Composite will be easy and clean released from bleeder cloths.

★ Allowing air, resin and volatile escaping during curing

PTFE Peel Ply has a higher porosity than normal PTFE coated fabric, which can allow air, resin and volatile pass through in the curing process.

★ Create super smooth surface for composite

After release, the composite will have a excellent smooth and shiny surface, such as bonnet of automotive.

★ Strong mechanical strength

Vacuum bagging bleeder cloths has high tensile strength, which can resist the high pressure in autoclave. And cloth will not be tore when releasing the peel ply.

| Product | Product Category | Coating |

|---|---|---|

| PTFE GLASS FABRIC | POROUS SERIES | PTFE |

| Properties | Metric | Imperial |

|---|---|---|

| Standard width Please ask for other widths | 1000 mm | 39.5 inches |

| Thickness | 0.06 mm(YS9006P) 0.075mm(YS9007P) | 0.0024 inches(YS9006P) 0.0030 inches(YS9007P) |

| Coated weight | 66 g/m² (YS9006P) 82 g/m² (YS9007P) | 1.95 oz/yd²(YS9006P) 2.42 oz/yd²(YS9007P) |

| PTFE content | 27 %(YS9006P) 28 %(YS9007P) | 27 %(YS9006P) 28 %(YS9007P) |

| Porosity | 20-100 cfm | 20-100 cfm |

| Tensile strength | 160 N/cm Warp | 91.5 lbs/inches Warp |

| 146 N/cm Fill | 83.5 lbs/inches Warp | |

| Temperature resistance | -73 to +260 °C | -100 to +500 °F |

Technical data sheet of Bleeder Cloth, YS9006P-ESONE, YS9007P-ESONE.

Leave A Comment