PTFE Fiberglass Fabric, release sheet for Plastic bag manufacturing

PTFE Fiberglass Fabric or PTFE self adhesive Fabrics are required to use in the process of plastic bags manufacturing. Because ESONE PTFE coated fabric can resist high welding operation temperature and offer a non stick surface, so the sealed bags can be easily released from the welding point.

Depending on the different process of polybag manufacturing, it may be preferred to use PTFE coated fabric as release sheet, or may require using adhesive backed PTFE coated fabric to stick into the welding part.

ESONE PTFE coated fiberglass fabric will be a important accessory for high speed plastic bags production equipment.

How to use PTFE Fiberglass Fabric

Plastic bag begin as plastic granules which are fed into machine, that heat and liquefied plastic. After that, thin plastic film will be extruded and rolled into a large roll. During the process of making plastic bags, the extruded poly film is formed, cut and sealed along three edges.

Plastic bags are made by sealing and cutting blown film with high temperature and speed. Plastic is heat welded to seal the outside edges of the bag.

This machine typically use a 2 ply PTFE conveyor belts to accomplish the heat seal, or use PTFE coated tape to stick to the heating point, which will offer easy release surface and heat resistant property for high speed welding.

Property of PTFE coated fabrics

★ Non-stick surface and easy release surface

★ Working continuous from -73°C – +260°C

★ Chemical resistant and environmental resistant

★ High tensile strength and dimensional stability

★ Reusable and has long lifetime

★ Abrasion and UV resistant

Another packaging application of Teflon coated fabric

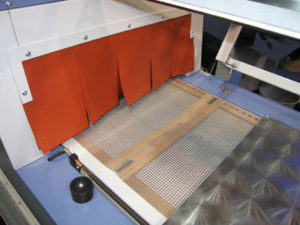

Heat Shrink Packaging

PVC or PE shrink film will be shrunken during high temperature or infrared radiation, and PTFE open mesh conveyor belt will convey the material through the oven, and Silicone coated fiberglass fabric curtains installed at both ends of the oven, serving to keep heat inside oven.

PTFE Fiberglass Fabric need to withstand high working temperature, and offer non stick surface to the plastic.

Heat sealing packaging

The vacuum sealing package is heat welded to close the bag, and one side or more sides of the package can be welded at one time in the actual process.

Teflon coated fabric or Self adhesive Teflon fiberglass tape will be required in the process, since ESONE product can resist high temperature and offer easy release surface.

Related product data sheet of Self adhesive PTFE Fiberglass Fabric: YS7008AJ-ESONE, YS7008BJ-ESONE, YS7013AJ-ESONE, YS7013AJY-ESONE, YS7013AT-ESONE, YS7015AJ-ESONE

Related product data sheet of PTFE coated fabric without adhesive: YS9008AJ-ESONE, YS9008BJ-ESONE, YS9013AJ-ESONE, YS9015AJ-ESONE, YS9018AJ-ESONE

Leave A Comment